Managing equipment fleets across customer sites shouldn't require complex enterprise systems, endless spreadsheets, and constant phone calls to the office. Yet most operations have evolved into exactly that - layers of tools, fragmented data, and workflows that work around system limitations rather than solving them.

There's a simpler way to think about this.

Effective equipment management comes down to two fundamentals: Visibility and Accessibility.

What Good Equipment Management Looks Like

Before diving into solutions, let's define the goal.

Good equipment management is:

- Knowing where every asset is and what state it's in - at a glance

- Anyone who needs information about an asset can access it - instantly

- Service history, documentation, and status are always current - and auditable

- Data flows from field interactions back into your systems - automatically

- Complexity is low - for your team, your technicians, and your customers

The Two Pillars: Visibility and Accessibility

Pillar 1: Visibility

Visibility means: Seeing your entire equipment fleet - location, status, condition - in real time.

For distributed equipment (units deployed at customer sites, across facilities, or in the field), visibility is the foundation of operational control.

What visibility enables:

| Capability | Operational Impact |

|---|---|

| Know where every asset is | Route optimization, utilization tracking |

| See status across the fleet | Proactive maintenance, reduced downtime |

| Identify patterns | Data-driven decisions, capacity planning |

| Track service history | Quality assurance, warranty management |

| Monitor compliance | Audit readiness, risk reduction |

Pillar 2: Accessibility

Accessibility means: The right information is available to the right person at the right moment - without friction.

This is where most operations fail. The data exists. The systems exist. But when someone is physically standing at an asset - a technician, an inspector, a customer - getting to that data requires:

- Logging into a system

- Searching through records

- Calling the office

- Waiting

Every step is friction. Friction slows service. Friction introduces errors. Friction frustrates your team and your customers.

What accessibility enables:

| Capability | Operational Impact |

|---|---|

| Instant asset identification | No searching, no guessing |

| On-site access to service history | Better service quality |

| Documentation at the asset | Compliance, troubleshooting efficiency |

| Self-service for customers | Reduced inbound coordination |

| Data capture at point of interaction | Accurate, timely records |

Bridging the Gap: What's Actually Needed

The solution isn't replacing your existing systems. ERP, CMMS, internal databases - these serve their purpose. The problem is the gap between those systems and the physical world.

What's needed is a bridge:

Physical Asset

↕

[Bridge]

↕

Digital Systems & Data

This bridge needs to:

- Connect to the physical asset - a reliable identifier that's always present

- Provide instant access - no apps, no friction

- Work for anyone - technicians, customers, inspectors, anyone who encounters the asset

- Link to existing systems - not replace them, extend them

- Capture data - turn field interactions into system records

- Scale simply - low implementation complexity, low maintenance

This is the layer most operations are missing. Not another system - a connection layer that makes existing systems accessible at the point of need.

How I Would Solve This: Thinkertags

Thinkertags is purpose-built for exactly this problem.

It's a digital transformation tool focused on one thing: bridging the gap between physical assets, digital data, and the people who need access.

Take your Asset Operations

into the 21st century.

See how Thinkertags brings your entire asset fleet to life.

Here's how it works:

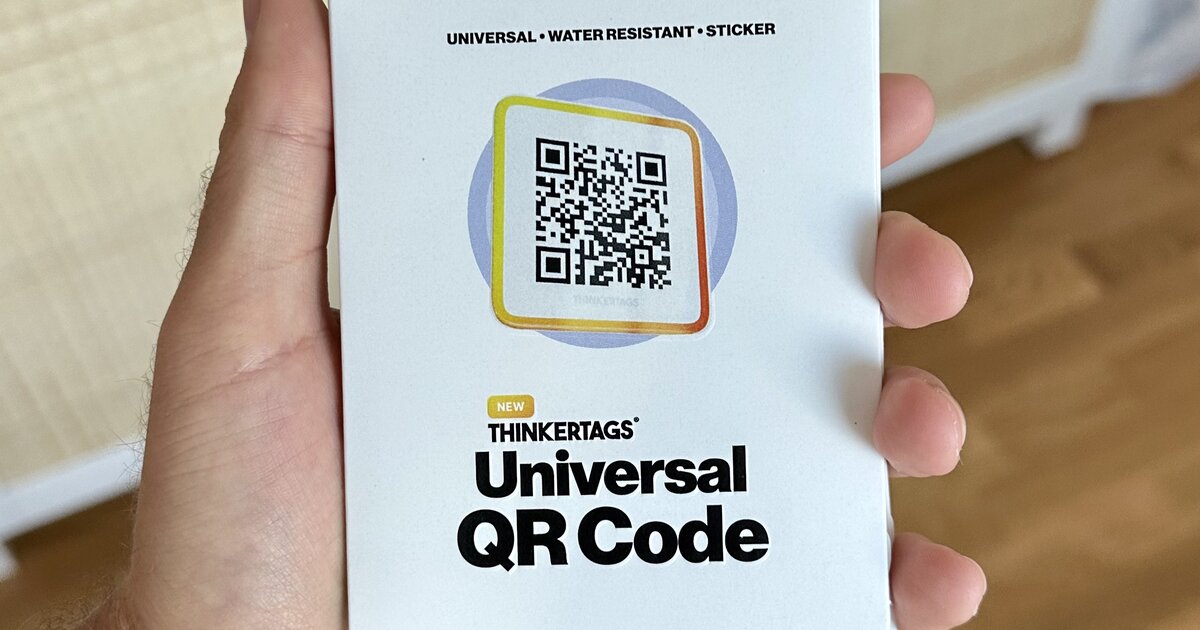

The Physical Layer: Smart Tags

Every asset gets a professional QR code tag - industrial-grade, weather-resistant, designed for 5+ years in harsh environments.

The tag is the permanent physical identifier. Scan it with any smartphone camera, and you're connected.

No app required. Works on any device.

The Access Layer: Instant Information

When someone scans a Thinkertags QR code, they get immediate access to:

Option A: Your Existing Systems

Link each tag to your current infrastructure:

- Direct link to the asset record in your ERP

- Direct link to work orders in your CMMS

- Links to documentation, manuals, training materials

- Up to 5 configurable destinations per asset

Thinkertags becomes the physical entry point to systems you've already invested in. No changes to those systems required.

Option B: StoreFront (Built-in Asset Profiles)

For capabilities your current systems lack, StoreFront provides lightweight asset management:

- Asset identification - name, image, serial number, custom fields

- Document management - attach manuals, certificates, inspection reports directly to the asset

- Status tracking - custom statuses (In Service, Maintenance Due, Out of Commission) with full audit trail

- Service requests - one-tap requests from the asset, arriving with complete context

- Private notes - internal information visible only to authenticated team members

Most operations use both - linking to existing systems for core data, using StoreFront for field-specific capabilities.

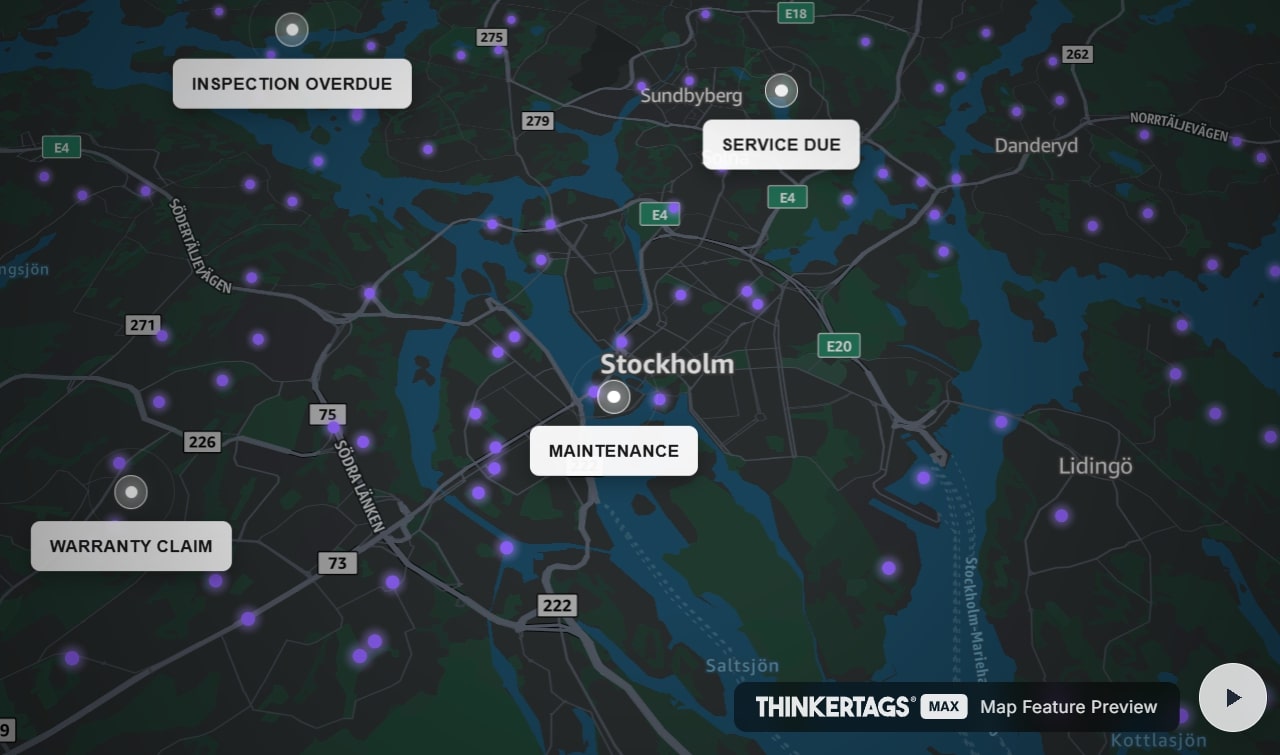

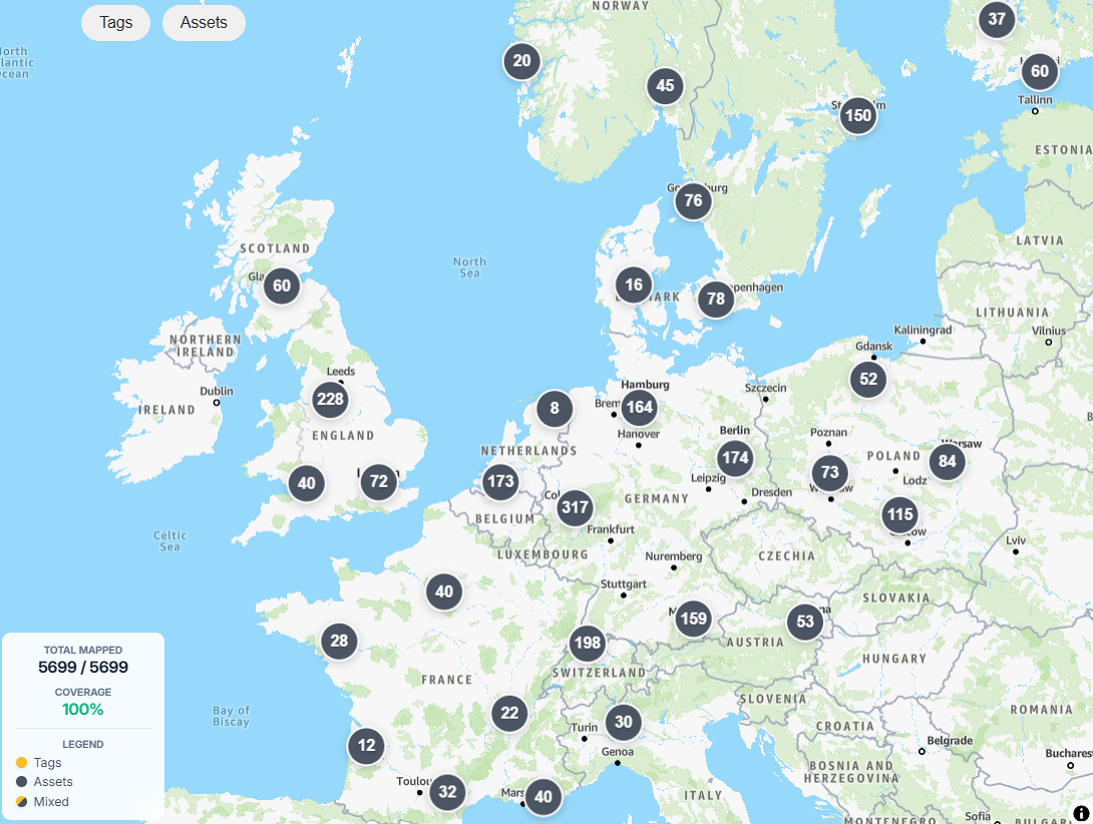

The Visibility Layer: Fleet Map

See your entire equipment fleet on an interactive map:

- Every asset plotted by location

- Filter by status, tag coverage, custom criteria

- Identify patterns across sites

- Proximity mode for on-site navigation

One view answers: "Where is everything, and what state is it in?"

The Data Layer: Capturing What Was Out of Reach

Every interaction with a Thinkertags-enabled asset generates data:

- Scan logs - who accessed what, when, from where

- Status changes - full history with user attribution

- Service requests - timestamped, contextualized, traceable

- Document access - which documentation is actually being used

This is data that previously didn't exist - field interactions that happened but never made it into your systems.

Now it flows automatically. Your operational picture becomes complete.

Why This Approach Works

Low Complexity

| Aspect | Thinkertags Approach |

|---|---|

| Implementation | Tag assets, configure links - operational in weeks |

| Training | Scanning QR codes requires no training |

| Maintenance | Cloud-hosted, no on-premise infrastructure |

| Integration | Links to existing systems, doesn't replace them |

High Impact

| Visibility Improvement | Accessibility Improvement |

|---|---|

| Real-time fleet status | Instant asset identification |

| Spatial view of all assets | Documentation at the asset |

| Complete service history | No-friction service requests |

| Audit-ready records | Self-service for customers |

| Data from every field interaction | No apps required |

Clear ROI

Direct savings:

- Technician time recovered from identification/documentation tasks

- Coordination time eliminated from service requests

- Audit preparation reduced from hours to minutes

Operational improvements:

- Service quality increases with complete information access

- Data accuracy improves with point-of-interaction capture

- Scalability improves without proportional overhead increase

Typical payback: Month 1.

What Thinkertags Is (And Isn't)

Thinkertags IS:

- An accessibility and visibility layer for physical assets

- A bridge between existing systems and the physical world

- A tool for capturing field interaction data

- A low-complexity, fast-deployment solution

- A complement to your existing infrastructure

Thinkertags IS NOT:

- A replacement for your ERP or CMMS

- A full asset management platform

- An IoT/sensor solution

- A complex enterprise deployment

If you need to replace core systems, Thinkertags isn't the answer. If you need to make your current systems accessible at the asset and gain visibility you don't currently have - that's exactly what this solves.

Does This Fit Your Operation?

Strong fit:

- Distributed assets at customer sites or across facilities

- Field teams servicing equipment who need on-site information

- 100+ assets under management

- Current gaps in visibility or accessibility

- Existing systems that work but aren't field-accessible

Not the right fit:

- All assets in a single supervised location

- Existing mobile-first system with strong field adoption

- Fewer than 50 assets

- Need for full ERP/CMMS replacement

Next Step

Evaluate first:

2-minute assessment - identify your visibility and accessibility gaps, get specific recommendations, and an opportunity to order a free product sample.

What's your asset visibility score?

Take our 2-minute assessment and get personalized recommendations for your asset management challenges.

Ready to discuss your asset management needs?

The Bottom Line

Equipment management doesn't need to be complicated.

Visibility and accessibility are the foundations. Most operations have gaps in both - not because their systems are bad, but because there's no connection between those systems and the physical equipment they manage.

Thinkertags bridges that gap. Simply. Affordably. In weeks, not months.

The result: streamlined operations, better data, improved service quality, and the control you should have had all along.

Thinkertags - Visibility and accessibility for distributed equipment operations.